Increased Efficiency and Productivity in Glass Handling with Pneumatic Glass Lifters

Glass handling has always been a delicate and time-consuming task. The fragility of glass makes it prone to breakage, and the weight of large glass panels can be a challenge to lift and maneuver. However, with the advent of pneumatic glass lifters, the future of glass handling is looking brighter than ever.

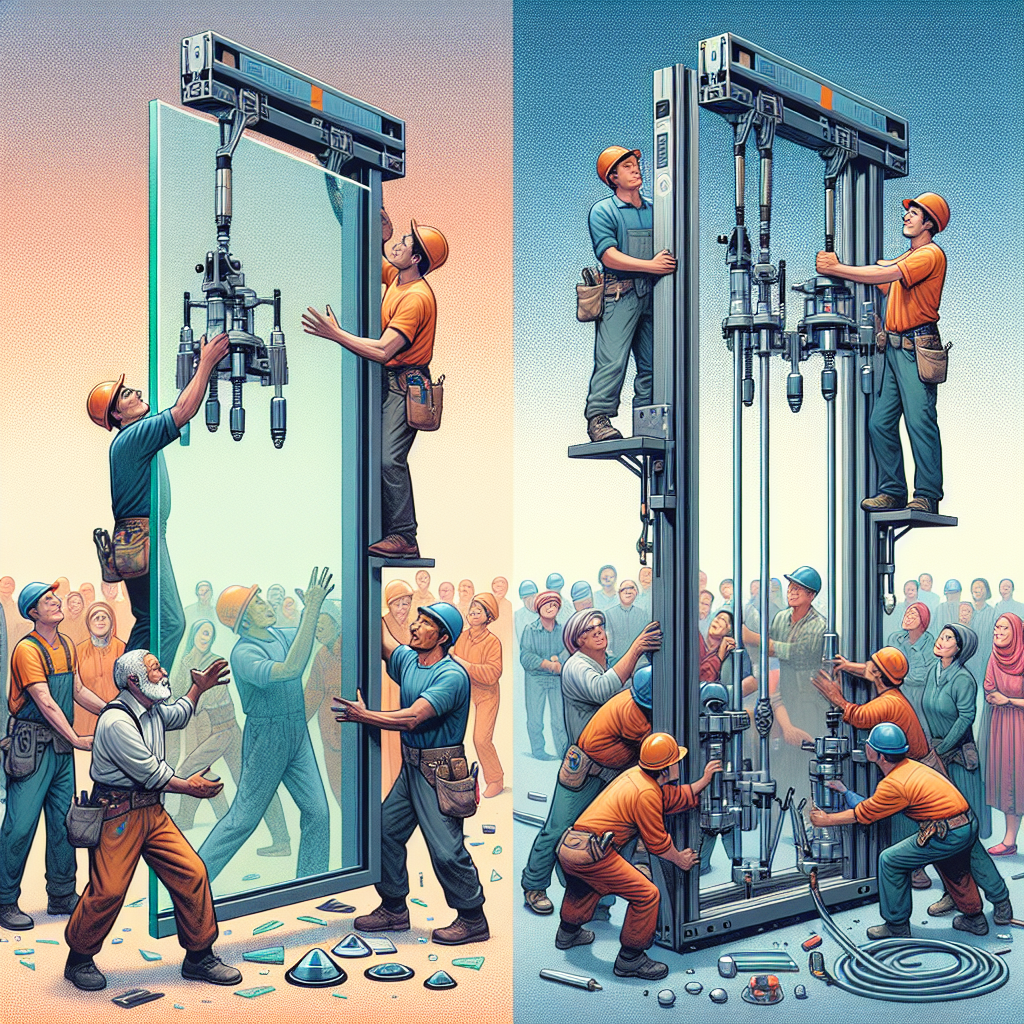

One of the key advantages of pneumatic glass lifters is their ability to increase efficiency and productivity in glass handling. Traditional methods of lifting and moving glass panels often require multiple workers and specialized equipment. This not only slows down the process but also increases the risk of accidents and damage to the glass.

Pneumatic glass lifters, on the other hand, are designed to streamline the glass handling process. These lifters use compressed air to create a vacuum seal between the lifter and the glass panel, allowing it to be lifted and moved with ease. This eliminates the need for multiple workers and reduces the risk of accidents and damage.

In addition to their efficiency, pneumatic glass lifters also offer increased productivity. With traditional methods, workers often have to take breaks to rest and recover from the physical strain of lifting heavy glass panels. This can significantly slow down the glass handling process and reduce overall productivity.

Pneumatic glass lifters, however, require minimal physical effort from the operator. The lifter does the heavy lifting, allowing workers to focus on other tasks and maintain a steady workflow. This not only increases productivity but also reduces the risk of worker fatigue and injuries.

Furthermore, pneumatic glass lifters are versatile and can handle a wide range of glass sizes and shapes. Whether it’s large glass panels or smaller, irregularly shaped pieces, these lifters can securely grip and lift them without any issues. This versatility eliminates the need for specialized equipment for different types of glass, further increasing efficiency and productivity.

Another advantage of pneumatic glass lifters is their precision and control. Traditional methods of glass handling often rely on manual labor, which can be imprecise and lead to accidental damage. Pneumatic glass lifters, on the other hand, offer precise control over the lifting and movement of glass panels.

Operators can easily adjust the lifter’s position and angle, ensuring that the glass is handled with care and precision. This reduces the risk of accidents and damage, resulting in higher-quality glass installations and satisfied customers.

In conclusion, pneumatic glass lifters are the future of glass handling due to their ability to increase efficiency and productivity. These lifters streamline the glass handling process, eliminating the need for multiple workers and reducing the risk of accidents and damage. They also offer increased productivity by minimizing physical strain on workers and allowing for a steady workflow. Additionally, pneumatic glass lifters are versatile, precise, and offer control over the lifting and movement of glass panels. With all these advantages, it’s clear that pneumatic glass lifters are revolutionizing the glass handling industry and paving the way for a more efficient and productive future.

Enhanced Safety Measures and Reduced Risk of Accidents with Pneumatic Glass Lifters

Glass handling can be a challenging and risky task, especially when dealing with large and heavy glass panels. Traditional methods of glass handling, such as manual lifting or using mechanical devices, have their limitations and can pose significant safety risks. However, with the advent of pneumatic glass lifters, the future of glass handling is looking brighter than ever.

One of the key advantages of pneumatic glass lifters is the enhanced safety measures they offer. These lifters are designed to minimize the risk of accidents and injuries during glass handling operations. Unlike manual lifting, which relies solely on human strength and coordination, pneumatic glass lifters utilize air pressure to lift and move glass panels. This eliminates the need for physical exertion and reduces the chances of strain or muscle fatigue.

Furthermore, pneumatic glass lifters are equipped with advanced safety features that further reduce the risk of accidents. For instance, many models come with vacuum suction cups that firmly grip the glass panels, preventing them from slipping or falling during transportation. These suction cups are designed to distribute the weight of the glass evenly, ensuring a secure and stable grip.

In addition to enhanced safety measures, pneumatic glass lifters also offer a reduced risk of accidents. The use of mechanical devices, such as cranes or forklifts, can be risky when it comes to glass handling. These devices often require manual operation and can be prone to human error. On the other hand, pneumatic glass lifters are automated and controlled by a single operator. This eliminates the need for multiple personnel and reduces the chances of miscommunication or mistakes.

Moreover, pneumatic glass lifters are designed to provide precise and controlled movements, further minimizing the risk of accidents. The operator can easily adjust the lifting speed and direction, ensuring smooth and accurate positioning of the glass panels. This level of control is crucial when working with delicate or fragile glass, as even the slightest mishap can result in costly damages.

Another significant advantage of pneumatic glass lifters is their versatility. These lifters can handle a wide range of glass sizes and shapes, making them suitable for various applications. Whether it’s lifting large glass panels for architectural purposes or handling smaller glass sheets for manufacturing, pneumatic glass lifters can adapt to different requirements. This versatility not only enhances efficiency but also reduces the need for multiple lifting devices, saving both time and resources.

In conclusion, pneumatic glass lifters are the future of glass handling due to their enhanced safety measures and reduced risk of accidents. These lifters offer advanced safety features, such as vacuum suction cups, to ensure a secure grip on glass panels. They also eliminate the need for manual lifting or the use of mechanical devices, reducing the chances of accidents caused by human error. Additionally, pneumatic glass lifters provide precise and controlled movements, minimizing the risk of damages to delicate glass. Their versatility further enhances efficiency and saves resources. With these advantages, it’s clear that pneumatic glass lifters are revolutionizing the glass handling industry and paving the way for a safer and more efficient future.

Cost-Effective and Versatile Solutions for Glass Handling with Pneumatic Glass Lifters

Glass handling can be a challenging and delicate task, requiring precision and care to avoid damage or injury. Traditional methods of glass handling, such as manual lifting or the use of cranes, can be time-consuming, labor-intensive, and costly. However, with the advent of pneumatic glass lifters, a new and innovative solution has emerged that offers cost-effective and versatile options for glass handling.

One of the key advantages of pneumatic glass lifters is their cost-effectiveness. Unlike traditional methods that require a large workforce or expensive machinery, pneumatic glass lifters can be operated by just one person. This not only reduces labor costs but also increases efficiency, as fewer workers are needed to complete the task. Additionally, the use of pneumatic glass lifters eliminates the need for expensive cranes or other heavy machinery, further reducing costs.

Another advantage of pneumatic glass lifters is their versatility. These lifters can be used for a wide range of glass handling tasks, from lifting and moving large glass panels to installing windows or glass partitions. The lifters are equipped with suction cups that securely grip the glass, allowing for safe and precise handling. The suction cups can be adjusted to accommodate different sizes and shapes of glass, making the lifters suitable for various applications.

Furthermore, pneumatic glass lifters offer a high level of control and precision. The lifters are equipped with a control panel that allows the operator to adjust the lifting speed, tilt angle, and rotation of the glass. This level of control ensures that the glass is handled with care and precision, minimizing the risk of damage or breakage. Additionally, the lifters are designed to provide a smooth and stable lifting motion, further reducing the risk of accidents or mishaps.

In addition to their cost-effectiveness and versatility, pneumatic glass lifters also offer several safety features. The lifters are equipped with sensors that detect any loss of vacuum or air pressure, immediately alerting the operator to potential issues. This ensures that the glass remains securely attached to the lifter at all times, reducing the risk of accidents or injuries. Furthermore, the lifters are designed with a fail-safe mechanism that prevents the glass from falling in the event of a power failure or other technical issues.

Overall, pneumatic glass lifters are the future of glass handling due to their cost-effectiveness, versatility, precision, and safety features. These lifters offer a more efficient and reliable solution for handling glass, reducing labor costs and increasing productivity. With their ability to handle a wide range of glass sizes and shapes, pneumatic glass lifters are suitable for various applications in industries such as construction, manufacturing, and architecture.

As the demand for glass continues to grow, the need for efficient and safe glass handling solutions becomes increasingly important. Pneumatic glass lifters provide a viable solution that addresses these needs, offering a cost-effective and versatile alternative to traditional methods. With their advanced features and capabilities, pneumatic glass lifters are poised to revolutionize the glass handling industry and become the go-to choice for businesses seeking efficient and reliable glass handling solutions.