Benefits of Using Vacuum Glass Lifters for Heavy Glass Handling

Vacuum Glass Lifter: An Innovative Solution for Heavy Glass Handling

When it comes to handling heavy glass, traditional methods can be time-consuming, labor-intensive, and even dangerous. However, with the advent of vacuum glass lifters, a new and innovative solution has emerged that revolutionizes the way heavy glass is handled. In this article, we will explore the benefits of using vacuum glass lifters for heavy glass handling.

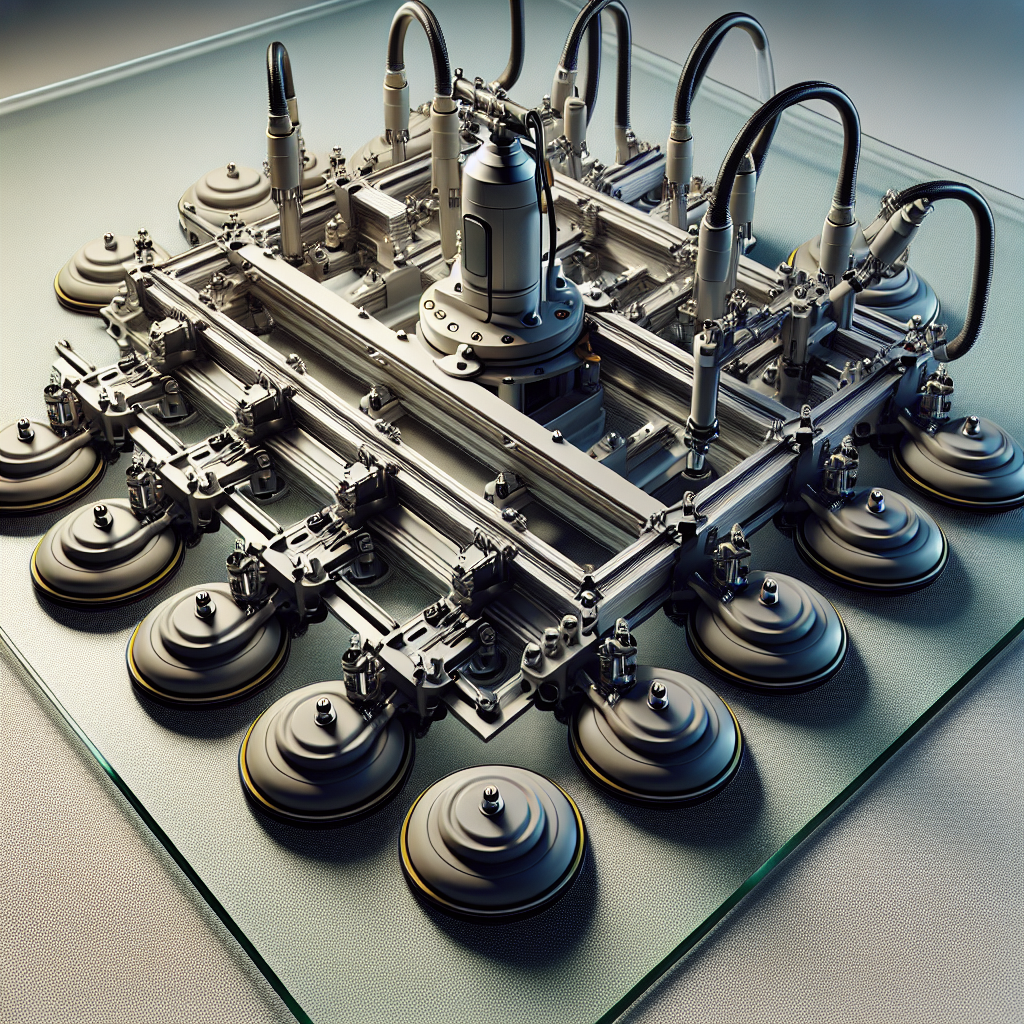

One of the primary advantages of vacuum glass lifters is their ability to lift and transport heavy glass with ease. Traditional methods often require multiple workers to manually lift and carry heavy glass, which not only puts a strain on the workers but also increases the risk of accidents and injuries. Vacuum glass lifters, on the other hand, utilize suction cups and a powerful vacuum system to securely grip and lift heavy glass, eliminating the need for manual lifting. This not only reduces the risk of injuries but also increases efficiency and productivity.

Another benefit of vacuum glass lifters is their versatility. These innovative devices can be used to handle a wide range of glass sizes and shapes, including large sheets, curved glass, and even fragile glass. The suction cups can be adjusted and positioned to accommodate different glass dimensions, ensuring a secure grip and safe transportation. This versatility makes vacuum glass lifters suitable for various industries, including construction, manufacturing, and glazing.

In addition to their versatility, vacuum glass lifters also offer precise control and maneuverability. Traditional methods of glass handling often require workers to rely on their physical strength and coordination to position and place heavy glass accurately. This can be challenging and time-consuming, especially when dealing with large or irregularly shaped glass. Vacuum glass lifters, on the other hand, are equipped with advanced control systems that allow for precise movements and adjustments. This not only saves time but also ensures that the glass is positioned correctly, reducing the risk of damage or accidents.

Furthermore, vacuum glass lifters contribute to a safer working environment. The suction cups create a secure and stable grip on the glass, minimizing the risk of slippage or dropping. This is particularly important when handling heavy or fragile glass, as any mishap can result in significant damage or injuries. By using vacuum glass lifters, companies can prioritize the safety of their workers and reduce the likelihood of accidents, ultimately saving time and money.

Lastly, vacuum glass lifters offer a cost-effective solution for heavy glass handling. While the initial investment may be higher compared to traditional methods, the long-term benefits outweigh the costs. Vacuum glass lifters increase productivity by reducing the time required for glass handling tasks. They also minimize the risk of damage, which can be costly to repair or replace. Additionally, by reducing the physical strain on workers, companies can lower the risk of injuries and associated medical expenses. Overall, vacuum glass lifters provide a cost-effective solution that improves efficiency, safety, and profitability.

In conclusion, vacuum glass lifters are an innovative solution for heavy glass handling. Their ability to lift and transport heavy glass with ease, versatility, precise control, and maneuverability, contribution to a safer working environment, and cost-effectiveness make them a valuable asset for various industries. By adopting vacuum glass lifters, companies can streamline their glass handling processes, improve worker safety, and enhance overall productivity.

How Vacuum Glass Lifters Improve Efficiency in Glass Installation

Vacuum Glass Lifter: An Innovative Solution for Heavy Glass Handling

Glass installation can be a challenging and time-consuming task, especially when dealing with heavy glass panels. Traditionally, manual labor and specialized equipment were required to lift and maneuver these delicate and cumbersome materials. However, with the advent of vacuum glass lifters, the process has been revolutionized, improving efficiency and reducing the risk of accidents.

One of the key advantages of vacuum glass lifters is their ability to handle heavy glass panels with ease. These lifters utilize the power of suction to securely grip the glass, allowing it to be lifted and moved effortlessly. This eliminates the need for multiple workers to manually lift and carry the glass, reducing the risk of strain or injury. Additionally, the use of vacuum glass lifters ensures a more precise and controlled handling of the glass, minimizing the chances of accidental damage.

Another significant benefit of vacuum glass lifters is their versatility. These lifters can be easily adjusted to accommodate different sizes and shapes of glass panels. Whether it’s a large floor-to-ceiling window or a small decorative glass piece, the vacuum glass lifter can be customized to fit the specific requirements of the installation. This flexibility not only saves time but also allows for a more efficient workflow, as there is no need to switch between different lifting mechanisms for different glass types.

Furthermore, vacuum glass lifters are designed to provide a secure and stable grip on the glass, even during transportation. This is particularly important when working at heights or in challenging environments. The vacuum suction cups create a strong bond with the glass surface, ensuring that it remains firmly in place throughout the lifting and moving process. This eliminates the risk of the glass slipping or falling, preventing potential accidents and damage.

In addition to improving efficiency and safety, vacuum glass lifters also contribute to a cleaner and more organized work environment. These lifters are equipped with built-in dust extraction systems, which remove any debris or particles that may accumulate on the glass surface. This not only enhances the visual appeal of the glass but also reduces the need for additional cleaning after installation. By eliminating the need for manual cleaning, vacuum glass lifters save both time and effort, allowing workers to focus on other aspects of the installation process.

In conclusion, vacuum glass lifters have revolutionized the way heavy glass panels are handled and installed. Their ability to securely grip and maneuver glass with ease improves efficiency, reduces the risk of accidents, and ensures a more precise and controlled handling of the material. The versatility of these lifters allows for easy adaptation to different glass sizes and shapes, further enhancing their efficiency. Additionally, the secure grip provided by vacuum glass lifters ensures the safety of workers and prevents accidental damage to the glass. Lastly, the built-in dust extraction systems contribute to a cleaner work environment, saving time and effort. With all these benefits, it is clear that vacuum glass lifters are an innovative solution for heavy glass handling, improving efficiency in glass installation.

Safety Measures and Best Practices for Operating Vacuum Glass Lifters

Safety Measures and Best Practices for Operating Vacuum Glass Lifters

When it comes to handling heavy glass, safety should always be the top priority. Glass is a fragile material that can easily break, causing serious injuries or damage. That’s why it’s crucial to follow proper safety measures and best practices when operating a vacuum glass lifter.

First and foremost, it’s important to ensure that the vacuum glass lifter is in good working condition. Regular maintenance and inspections should be conducted to check for any defects or malfunctions. Any issues should be addressed immediately to prevent accidents or injuries.

Before operating the vacuum glass lifter, it’s essential to assess the weight and size of the glass being lifted. The lifter should have a weight capacity that matches the glass being handled. Overloading the lifter can lead to instability and potential accidents. It’s also important to consider the size and shape of the glass, as it may require additional support or specialized equipment.

Proper training is crucial for anyone operating a vacuum glass lifter. Operators should be trained on how to use the lifter correctly, as well as how to handle glass safely. They should be familiar with the lifter’s controls and understand how to operate it safely. Training should also cover proper lifting techniques and how to secure the glass to prevent it from slipping or falling.

When using a vacuum glass lifter, it’s important to ensure that the glass is clean and free from any debris or contaminants. Dirt or dust can affect the suction power of the lifter, making it less effective and potentially causing the glass to slip. Cleaning the glass before lifting it will help ensure a secure grip and prevent accidents.

Another important safety measure is to always use appropriate personal protective equipment (PPE) when operating a vacuum glass lifter. This may include safety glasses, gloves, and steel-toed boots. PPE will help protect operators from any potential hazards, such as broken glass or falling debris.

Communication is key when operating a vacuum glass lifter. Operators should have clear lines of communication with other team members involved in the lifting process. This can be done through hand signals or two-way radios. Clear communication will help ensure that everyone is on the same page and can react quickly in case of an emergency.

When lifting glass, it’s important to be aware of the surrounding environment. The area should be clear of any obstacles or hazards that could interfere with the lifting process. It’s also important to consider the weather conditions, as wind or rain can affect the stability of the glass and the lifter. If necessary, additional precautions should be taken to secure the glass and prevent accidents.

Lastly, it’s important to have a plan in place for emergencies. Operators should be trained on what to do in case of a power failure or if the glass starts to slip. Having a backup plan and knowing how to react quickly can help prevent accidents and minimize damage.

In conclusion, operating a vacuum glass lifter requires strict adherence to safety measures and best practices. Regular maintenance, proper training, and the use of personal protective equipment are essential for safe operation. Clear communication, a clean lifting surface, and awareness of the surrounding environment are also crucial. By following these guidelines, operators can ensure the safe handling of heavy glass and prevent accidents or injuries.