Efficiency and Productivity: Pneumatic Glass Lifter vs. Manual Lifting

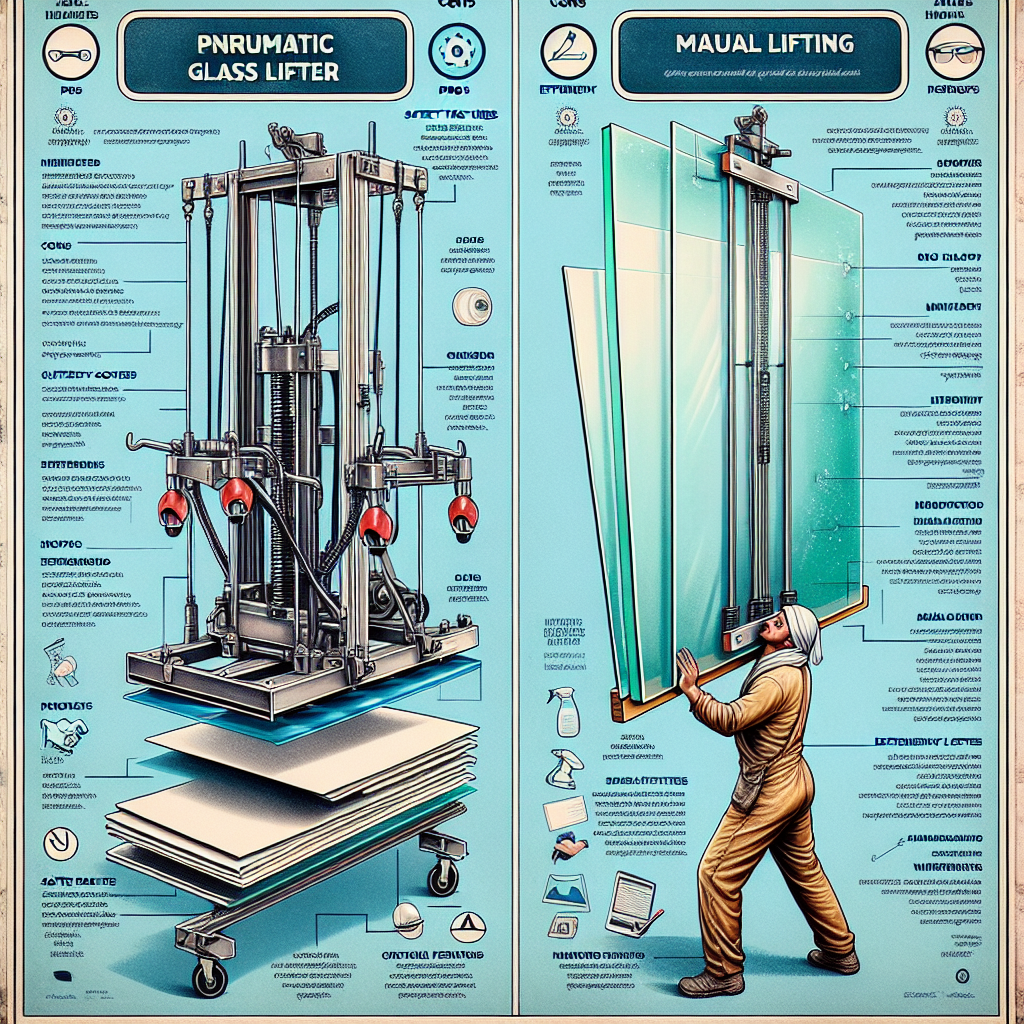

Efficiency and productivity are crucial factors to consider when it comes to lifting heavy objects, such as glass. In this article, we will compare the efficiency and productivity of using a pneumatic glass lifter versus manual lifting. By examining the advantages and disadvantages of each method, we can determine which option is more suitable for various lifting tasks.

Pneumatic glass lifters are powered by compressed air, making them highly efficient in lifting heavy glass panels. These lifters are equipped with suction cups that create a vacuum seal, allowing them to securely grip the glass. The use of compressed air provides a consistent and reliable lifting force, ensuring that the glass is lifted smoothly and without any sudden movements. This not only reduces the risk of accidents but also minimizes the chances of damaging the glass.

On the other hand, manual lifting involves physically lifting the glass using manpower. While this method may be suitable for smaller glass panels or lighter loads, it becomes increasingly challenging and time-consuming for larger and heavier glass panels. Manual lifting requires a significant amount of physical strength and can put strain on the back, shoulders, and arms of the workers. This can lead to fatigue and potential injuries, which can ultimately affect productivity.

In terms of efficiency, pneumatic glass lifters have a clear advantage. These lifters can lift and transport glass panels with ease, significantly reducing the time and effort required for the task. The suction cups provide a secure grip, allowing workers to move the glass quickly and efficiently. Additionally, pneumatic glass lifters often come with adjustable features, such as tilt and rotation, which further enhance their efficiency and versatility.

Manual lifting, on the other hand, is a labor-intensive process that relies solely on the physical strength of the workers. This method is not only slower but also more prone to errors and accidents. The lack of a secure grip can result in the glass slipping or falling, leading to breakage and potential injuries. Moreover, manual lifting may require multiple workers to lift and transport larger glass panels, further reducing productivity.

When it comes to productivity, pneumatic glass lifters undoubtedly outperform manual lifting. The speed and ease with which these lifters can handle glass panels allow workers to complete tasks more efficiently. This increased productivity not only saves time but also reduces labor costs, making pneumatic glass lifters a cost-effective option in the long run.

However, it is important to note that pneumatic glass lifters may not be suitable for all lifting tasks. Certain factors, such as the size and weight of the glass panels, as well as the accessibility of the work area, need to be considered. In some cases, manual lifting may still be the preferred option, especially when dealing with smaller glass panels or when maneuvering in tight spaces.

In conclusion, when it comes to efficiency and productivity, pneumatic glass lifters have a clear advantage over manual lifting. The use of compressed air provides a consistent and reliable lifting force, allowing for smooth and secure glass handling. Pneumatic glass lifters not only save time and effort but also reduce the risk of accidents and damage to the glass. However, it is important to assess the specific lifting requirements before deciding on the most suitable method.

Safety Considerations: Pneumatic Glass Lifter vs. Manual Lifting

Safety Considerations: Pneumatic Glass Lifter vs. Manual Lifting

When it comes to lifting heavy objects, safety should always be a top priority. This is especially true when it comes to lifting glass, which is fragile and can easily break if mishandled. In this article, we will compare the safety considerations of using a pneumatic glass lifter versus manual lifting.

One of the main advantages of using a pneumatic glass lifter is that it reduces the risk of injury. Manual lifting can put a strain on the back, shoulders, and arms, leading to muscle strains, sprains, and even more serious injuries. With a pneumatic glass lifter, the lifting is done by a machine, which eliminates the need for manual exertion. This significantly reduces the risk of injury and allows for safer glass handling.

In addition to reducing the risk of injury, a pneumatic glass lifter also provides better control and stability. When lifting glass manually, there is always a risk of the glass slipping or falling, which can result in shattered glass and potential injuries. A pneumatic glass lifter, on the other hand, uses suction cups to securely grip the glass, providing a stable and controlled lifting process. This ensures that the glass remains in place and minimizes the risk of accidents.

Furthermore, a pneumatic glass lifter allows for easier maneuverability. Glass can be heavy and awkward to lift, especially in tight spaces or when navigating obstacles. Manual lifting in such situations can be challenging and increase the risk of accidents. With a pneumatic glass lifter, however, the machine can be easily maneuvered to lift and transport the glass with precision, even in confined spaces. This not only makes the lifting process safer but also reduces the risk of damage to the glass or surrounding objects.

Another safety consideration when comparing pneumatic glass lifters to manual lifting is the risk of fatigue. Manual lifting can be physically demanding, especially when lifting heavy glass repeatedly throughout the day. This can lead to fatigue, which can impair judgment and increase the risk of accidents. With a pneumatic glass lifter, the lifting is done by the machine, reducing the physical strain on the operator and minimizing the risk of fatigue-related accidents.

It is worth noting, however, that while pneumatic glass lifters offer numerous safety advantages, they do require proper training and maintenance to ensure safe operation. Operators must be trained on how to use the equipment correctly and be aware of any potential hazards. Regular maintenance and inspections are also necessary to ensure that the pneumatic glass lifter is in good working condition and that all safety features are functioning properly.

In conclusion, when it comes to safety considerations, a pneumatic glass lifter offers several advantages over manual lifting. It reduces the risk of injury, provides better control and stability, allows for easier maneuverability, and minimizes the risk of fatigue-related accidents. However, it is important to remember that proper training and maintenance are essential for safe operation. By carefully considering these factors, you can make an informed decision on whether a pneumatic glass lifter is the right choice for your glass lifting needs.

Cost Analysis: Pneumatic Glass Lifter vs. Manual Lifting

Cost Analysis: Pneumatic Glass Lifter vs. Manual Lifting

When it comes to lifting heavy glass panels, there are two main options to consider: using a pneumatic glass lifter or relying on manual lifting. Both methods have their advantages and disadvantages, but one crucial factor that often influences the decision-making process is cost. In this section, we will delve into the cost analysis of using a pneumatic glass lifter versus manual lifting, providing a detailed comparison to help you make an informed choice.

First and foremost, let’s consider the initial investment required for each option. Purchasing a pneumatic glass lifter can be quite expensive, with prices ranging from a few hundred to several thousand dollars, depending on the lifting capacity and additional features. On the other hand, manual lifting does not require any significant upfront investment, as it relies solely on human labor. However, it is important to note that manual lifting may require the use of additional equipment, such as suction cups or lifting straps, which can add to the overall cost.

Moving on to operational costs, pneumatic glass lifters have a clear advantage. These devices are powered by compressed air, which is generally more cost-effective than relying on human labor. Pneumatic glass lifters are designed to be energy-efficient, ensuring that you can lift multiple glass panels without incurring substantial electricity costs. In contrast, manual lifting relies solely on human strength and endurance, which can lead to fatigue and decreased productivity over time. This may result in the need for additional workers or longer working hours, ultimately increasing labor costs.

Another aspect to consider is maintenance and repair costs. Pneumatic glass lifters, like any mechanical device, require regular maintenance to ensure optimal performance and longevity. This includes routine inspections, lubrication, and occasional repairs. While these maintenance costs can add up over time, they are generally predictable and can be factored into the overall cost analysis. On the other hand, manual lifting does not involve any significant maintenance costs, as it relies solely on human effort. However, it is important to consider the potential for workplace injuries and the associated costs, such as medical expenses and workers’ compensation claims, which can arise from manual lifting.

Furthermore, it is essential to consider the impact of each lifting method on productivity and efficiency. Pneumatic glass lifters are specifically designed to streamline the lifting process, allowing for faster and more precise glass panel installation. This increased efficiency can result in significant time savings, ultimately reducing labor costs. Manual lifting, on the other hand, is more time-consuming and requires a higher level of physical exertion. This can lead to decreased productivity and potential delays in completing projects, which can have financial implications.

In conclusion, when comparing the cost of using a pneumatic glass lifter versus manual lifting, it is crucial to consider various factors. While pneumatic glass lifters require a significant initial investment, they offer long-term cost savings through energy efficiency and increased productivity. On the other hand, manual lifting may seem more cost-effective initially, but it can lead to higher labor costs, potential workplace injuries, and decreased efficiency. Ultimately, the choice between these two methods depends on the specific needs and budget of your project.