Benefits of Using a Pneumatic Glass Lifter for Increased Efficiency

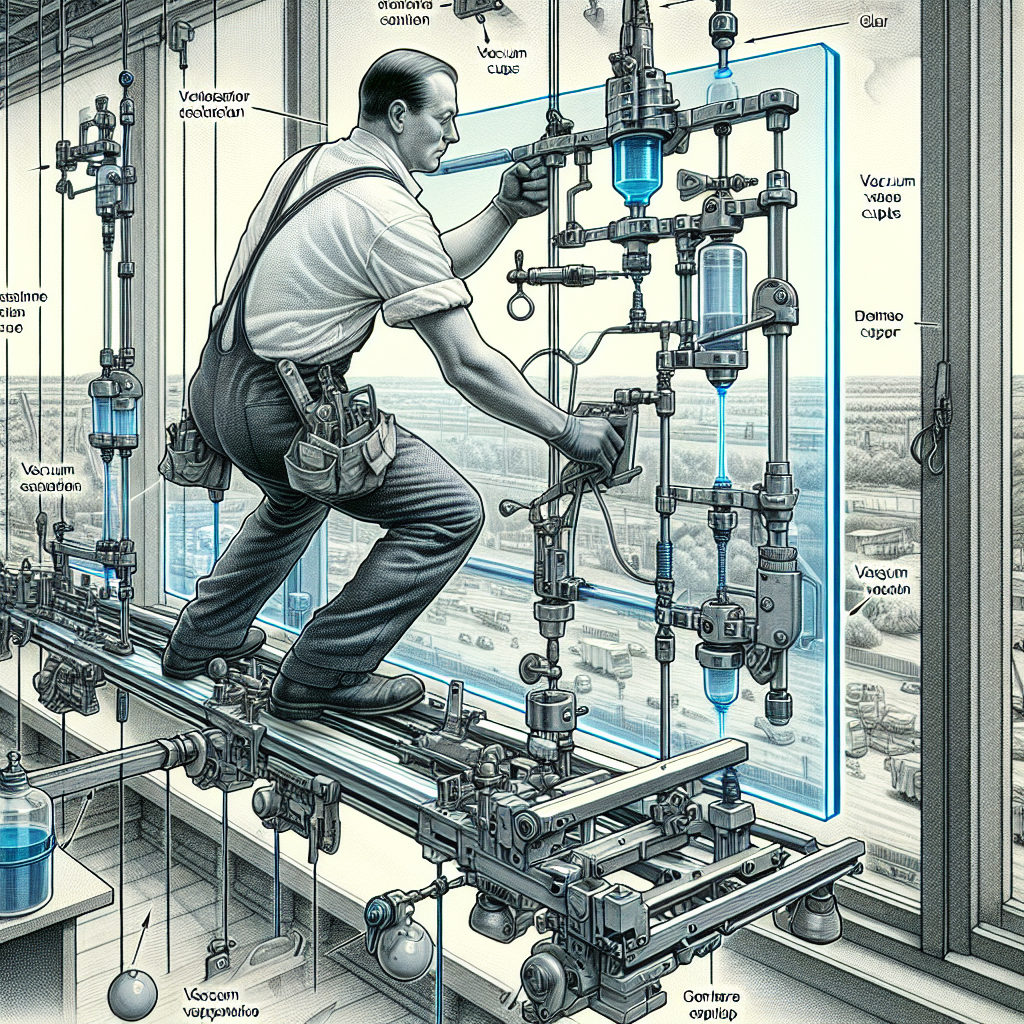

A pneumatic glass lifter is a powerful tool that can greatly increase efficiency in various industries. Whether you work in construction, manufacturing, or any other field that involves handling glass, this innovative device can streamline your operations and save you time and effort. In this article, we will explore the benefits of using a pneumatic glass lifter for increased efficiency.

One of the key advantages of a pneumatic glass lifter is its ability to lift and transport heavy glass panels with ease. Traditional methods of lifting glass, such as using suction cups or manual labor, can be time-consuming and physically demanding. With a pneumatic glass lifter, you can effortlessly lift and move glass panels weighing up to several hundred pounds. This not only reduces the risk of injury to workers but also allows for faster and more efficient handling of glass.

Another benefit of using a pneumatic glass lifter is its versatility. These devices come in various sizes and configurations, allowing you to choose the one that best suits your specific needs. Whether you need to lift small glass sheets or large, heavy panels, there is a pneumatic glass lifter available for the job. Additionally, some models are equipped with adjustable suction cups, which can accommodate glass panels of different shapes and sizes. This versatility ensures that you can handle a wide range of glass products efficiently and effectively.

In addition to its lifting capabilities, a pneumatic glass lifter also offers precise control over glass positioning. This is particularly important when working with delicate or fragile glass, as even the slightest mishandling can result in costly damage. With a pneumatic glass lifter, you can easily maneuver glass panels into the desired position, ensuring accurate placement and minimizing the risk of breakage. This level of control not only saves time but also reduces waste and associated costs.

Furthermore, a pneumatic glass lifter can significantly speed up the installation process. Traditional methods of installing glass, such as using scaffolding or cranes, can be time-consuming and require multiple workers. With a pneumatic glass lifter, a single operator can quickly and efficiently install glass panels, eliminating the need for additional manpower. This not only saves time but also reduces labor costs, making it a cost-effective solution for glass installation projects.

Lastly, a pneumatic glass lifter can improve overall workplace safety. By reducing the need for manual lifting and handling of heavy glass panels, the risk of injuries and accidents is significantly reduced. Additionally, these devices are equipped with safety features such as audible alarms and visual indicators, which alert operators to any potential issues or malfunctions. This ensures that workers can operate the equipment safely and effectively, further enhancing efficiency in the workplace.

In conclusion, a pneumatic glass lifter offers numerous benefits for increased efficiency in various industries. From lifting heavy glass panels with ease to providing precise control over glass positioning, these devices streamline operations and save time and effort. Their versatility, speed, and safety features make them an invaluable tool for any business that deals with glass. By investing in a pneumatic glass lifter, you can enhance productivity, reduce costs, and improve overall workplace efficiency.

Tips for Proper Maintenance and Care of Pneumatic Glass Lifters

Pneumatic glass lifters are essential tools for handling and transporting glass panels in various industries. These lifters use compressed air to create a vacuum, allowing them to securely grip and lift heavy glass sheets. To ensure the longevity and optimal performance of your pneumatic glass lifter, proper maintenance and care are crucial. In this article, we will provide you with some valuable tips on how to increase efficiency with a pneumatic glass lifter through proper maintenance and care.

First and foremost, it is essential to regularly inspect your pneumatic glass lifter for any signs of wear and tear. Check the vacuum cups for cracks or damage, as these are the components that come into direct contact with the glass. If you notice any issues, replace the damaged cups immediately to prevent any accidents or damage to the glass panels.

Additionally, it is crucial to keep the vacuum cups clean and free from debris. Dust, dirt, and other particles can affect the lifter’s ability to create a strong vacuum seal, compromising its efficiency. Regularly clean the cups with a mild detergent and warm water, ensuring that they are completely dry before using the lifter.

Furthermore, pay close attention to the condition of the vacuum pump. The pump is responsible for creating the necessary suction force to lift the glass panels. Inspect the pump for any leaks or unusual noises. If you notice any issues, have a professional technician inspect and repair the pump to maintain the lifter’s efficiency.

Another important aspect of maintaining a pneumatic glass lifter is ensuring that the lifting frame and other mechanical components are properly lubricated. Lubrication reduces friction and wear, allowing the lifter to operate smoothly and efficiently. Use a high-quality lubricant recommended by the manufacturer and follow the recommended lubrication schedule.

In addition to regular maintenance, proper storage of the pneumatic glass lifter is crucial for its longevity. When not in use, store the lifter in a clean and dry environment, away from extreme temperatures and direct sunlight. This will prevent any damage to the lifter’s components and ensure its optimal performance when needed.

Furthermore, it is essential to train and educate the operators on the proper use of the pneumatic glass lifter. Improper handling can lead to accidents, damage to the glass panels, and decreased efficiency. Provide comprehensive training on how to operate the lifter safely and efficiently, emphasizing the importance of following the manufacturer’s guidelines and safety protocols.

Lastly, regularly assess the efficiency and performance of your pneumatic glass lifter. Keep track of any issues or inefficiencies that arise during operation and address them promptly. This may involve adjusting the vacuum pressure, replacing worn-out components, or seeking professional assistance for more complex problems.

In conclusion, proper maintenance and care are essential for increasing efficiency with a pneumatic glass lifter. Regular inspections, cleaning, lubrication, and storage will ensure the longevity and optimal performance of the lifter. Additionally, providing proper training to operators and addressing any issues promptly will contribute to a safer and more efficient glass handling process. By following these tips, you can maximize the efficiency of your pneumatic glass lifter and enhance productivity in your industry.

Step-by-Step Guide on Using a Pneumatic Glass Lifter for Maximum Efficiency

How to Increase Efficiency with a Pneumatic Glass Lifter

In today’s fast-paced world, efficiency is key. Whether you’re a construction worker, a glazier, or simply someone who needs to move heavy glass panels, finding ways to increase efficiency can save you time, money, and energy. One tool that can greatly improve efficiency in glass handling is a pneumatic glass lifter. In this step-by-step guide, we will explore how to use a pneumatic glass lifter for maximum efficiency.

Step 1: Familiarize Yourself with the Equipment

Before using a pneumatic glass lifter, it is important to familiarize yourself with the equipment. This includes understanding its components, such as the vacuum pads, the control panel, and the lifting arm. Take the time to read the user manual and ensure that you have a clear understanding of how the lifter operates.

Step 2: Inspect the Glass and the Lifting Surface

Before attempting to lift any glass panels, it is crucial to inspect both the glass and the lifting surface. Check for any cracks, chips, or other damage on the glass that could compromise its integrity. Similarly, inspect the lifting surface to ensure that it is clean, level, and free from any debris that could interfere with the lifter’s suction.

Step 3: Position the Glass Lifter

Once you have inspected the glass and the lifting surface, position the glass lifter in the desired location. Make sure that the lifter is stable and secure before proceeding. If necessary, use additional support equipment, such as suction cups or clamps, to ensure that the lifter remains in place during the lifting process.

Step 4: Activate the Vacuum Pads

With the lifter in position, activate the vacuum pads by turning on the control panel. This will create a suction force that securely attaches the lifter to the glass panel. Take a moment to verify that the vacuum pads are properly attached and that there are no leaks or loss of suction.

Step 5: Lift the Glass

Once the vacuum pads are securely attached, it is time to lift the glass. Use the control panel to activate the lifting arm, gradually applying upward pressure until the glass is lifted off the surface. Take care to lift the glass slowly and evenly to avoid any sudden movements or shifts that could cause damage.

Step 6: Maneuver and Position the Glass

With the glass lifted, you can now maneuver and position it as needed. The pneumatic glass lifter allows for precise control, making it easier to navigate tight spaces or adjust the glass to the desired angle. Take your time and make any necessary adjustments before proceeding.

Step 7: Lower and Release the Glass

Once the glass is in its final position, it is time to lower and release it. Use the control panel to gradually lower the glass back onto the lifting surface, taking care to ensure a smooth and controlled descent. Once the glass is safely on the surface, release the vacuum pads by deactivating the control panel.

By following these step-by-step instructions, you can effectively use a pneumatic glass lifter to increase efficiency in glass handling. Remember to always prioritize safety and take the time to familiarize yourself with the equipment before use. With practice, you will become more proficient in using a pneumatic glass lifter, saving time and effort in your glass handling tasks.